EMTC – MULTI-PURPOSE MECHANICAL MANUFACTURING EXPERT

13/05/2025With the motto “Quality – Precision – Reliability,” EMTC proudly stands as a leading partner in mechanical production, delivering comprehensive solutions for the most demanding technical requirements. Our team of seasoned engineers, state-of-the-art machinery, and rigorous quality controls ensure every metal component meets the highest standards of strength, accuracy, and aesthetics.

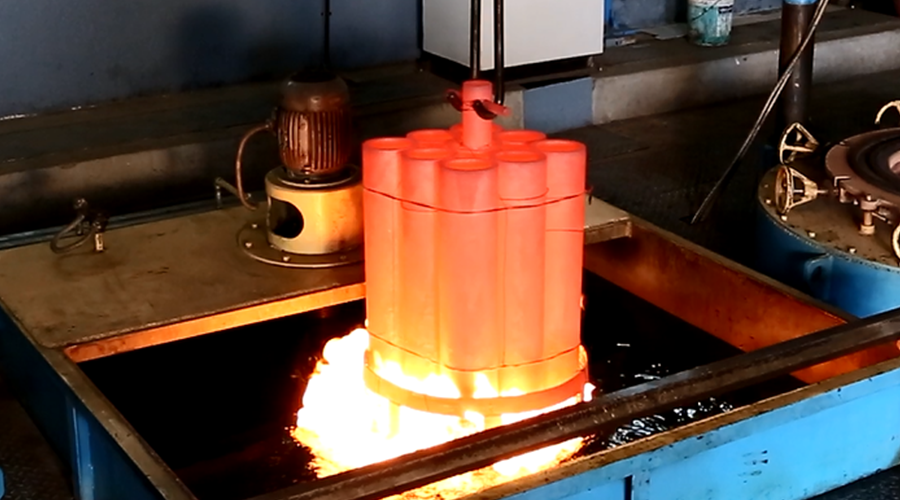

1. Hot Forging

-

-

Utilizes high heat and powerful presses to shape metal.

-

Benefits: enhances mechanical strength, refines material structure, and minimizes internal defects.

-

2. Precision Machining

-

Turning: CNC and semi-automatic lathes produce cylindrical parts with ultra-tight tolerances.

-

Milling: Creates flat surfaces, slots, and contours with superior surface finish.

-

Drilling: Accurately positions and sizes holes in metal components.

-

Grinding: Achieves micron-level tolerances and mirror-smooth surfaces.

-

Bending: Forms sheet and bar stock into complex profiles.

-

Multi-step Progressive Forming: Sequential stamping operations within a single die system.

3. Welding & Cold Stamping

-

Automated and robotic welding for high-strength, visually flawless joints.

-

Cold stamping of sheet metal to produce intricate shapes without material distortion.

4. Sheet Metal Processing

-

Laser cutting, plasma cutting, and precision shearing deliver razor-sharp edges.

-

Bending, stamping, and welding create sheet metal parts with millimeter accuracy.

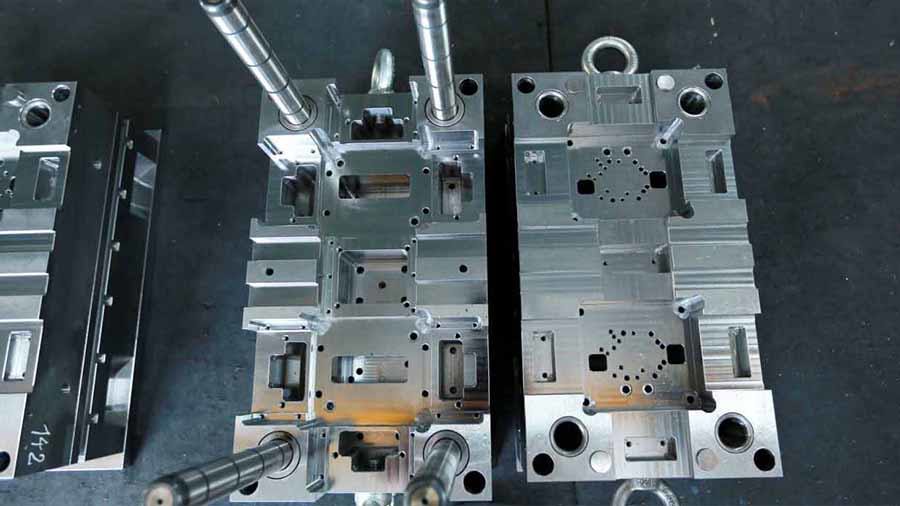

5. Mold & Jig Manufacturing

-

Design and fabricate robust forging and stamping dies with extended service life.

-

Produce custom jigs and fixtures to streamline assembly processes and boost productivity.

6. Heat Treatment

-

Apply quenching, tempering, and annealing to tailor hardness and toughness.

-

Precisely control temperature and timing to ensure uniform results.

7. Surface Treatment

-

Powder coating, electroplating (zinc, nickel), and polishing.

-

Enhance corrosion resistance, durability, and visual appeal.

Our Commitments

-

International Quality Standards: ISO 9001:2015 certified with strict in-process inspections.

-

On-Time Delivery: Optimized production scheduling to meet deadlines—even for rush orders.

-

Competitive Pricing: Cost-efficient processes and transparent quotations.

-

24/7 Technical Support: Consultation, design assistance, and parameter adjustments as needed.

Let EMTC partner with you from concept drawings to finished components. Contact us today for detailed consultation and fast, competitive quotes!